Study on thermal characteristics of 266 nm deep ultraviolet laser generated by BBO crystal - 02

Experimental Setup

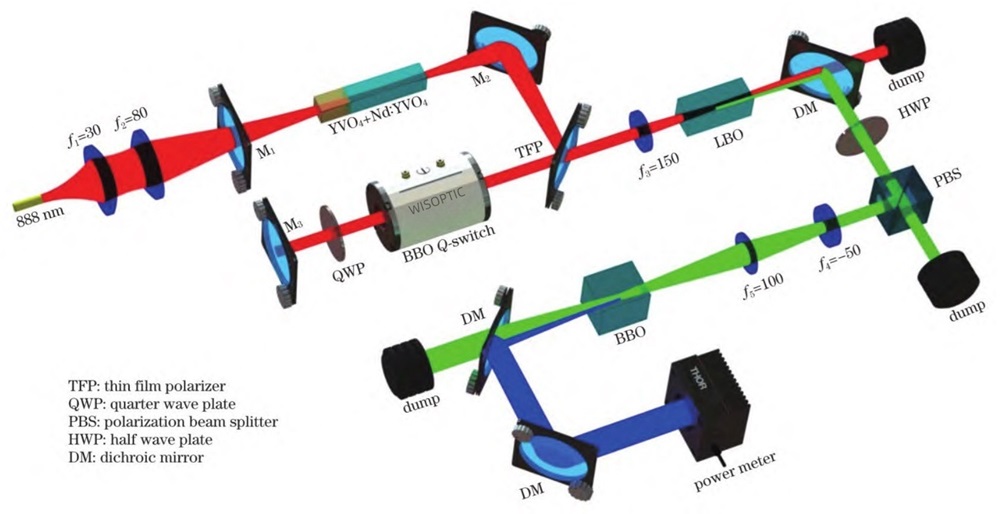

In order to obtain a 266 nm deep ultraviolet laser with high efficiency and stable operation, this paper built an all-solid-state 266 nm deep ultraviolet laser generation device as shown in Figure 1, which consists of a cavity-dumped all-solid-state Nd:YVO4 laser, a double-frequency system, and a quadruple-frequency system.

Fig. 1 Experimental setup of the all-solid-state 266 nm DUV laser

The all-solid-state Nd:YVO4 near-infrared laser is used as the fundamental frequency light source for generating the fourth harmonic 266 nm deep ultraviolet laser, and its resonant cavity adopts a plano-convex standing wave cavity structure. In order to effectively slow down the quantum loss thermal effect of the gain crystal, a semiconductor laser with a central wavelength of 888 nm is selected as the pump source, and its output beam is collimated and focused onto the gain medium Nd:YVO4 crystal through a telescope system composed of lenses with focal lengths (f1, f2) of 30 mm and 80 mm respectively, to achieve mode matching between the pump laser and the resonant cavity. In order to mitigate the thermal effect of the front face of the crystal, the gain crystal uses a YVO4+Nd:YVO4 (www.wisoptic.com) bonded crystal with a size of 3 mm×3 mm×(3+20) mm, and the atomic fraction of neodymium ions is 0.8%. Both ends of the crystal are coated with 888/1064 nm anti-reflection (AR) film and cooled with a circulating water system. The input mirror M1 uses a plano-convex mirror with a curvature radius of 700 mm and is coated with an 888 nm AR film and a 1064 nm high-reflection (HR) film; the cavity mirror M2 is a plane mirror coated with an 888 nm AR film and a 1064 nm HR film; the cavity mirror M3 uses a plane mirror coated with a 1064 nm HR film, and a 45° 1064 nm thin-film polarizer (TFP) is used as the output mirror of the resonant cavity. A BBO electro-optic crystal (BBO Q-switch, www.wisoptic.com) and a quarter wave plate (QWP) were inserted between TFP and M3. The voltage applied to both ends of the BBO Q-switch was adjusted to change the transmittance of the output mirror TFP. Finally, a stable cavity dumping operation was achieved under a high voltage load of 3.6 kV, and the TFP output a horizontally polarized 1064 nm fundamental frequency light source.

The 1064 nm laser is shaped and focused into the double frequency crystal by lens f3 (focal length is 150 mm), generating the second harmonic 532 nm green light. In order to obtain a smaller walk-off effect and a higher double frequency efficiency, a type I non-critical phase-matched LBO crystal (www.wisoptic.com) was used to be the double frequency medium. The crystal cutting angle is θ=90°, φ=0°, the size is 3 mm×3 mm×20 mm, and both ends of the crystal are AR coated at 1064/532 nm. In the experiment, the LBO crystal is placed in a copper furnace with constant temperature which contains a heater and a temperature sensor, and heated to 148.5 ℃, with temperature control accuracy of ±0.01 ℃.

After the 532 nm laser is separated from the 1064 nm fundamental frequency light by the 1064/532 nm dichroic mirror (DM), it is expanded and shaped by a telescope system composed of lenses f4 and f5 (focal lengths of -50 mm and 100 mm, respectively), and injected into the BBO crystal for quadrupling. At the same time, in order to facilitate the experiment, a half-wave plate (HWP) is used in conjunction with a polarization beam splitter (PBS) to adjust the power of the 532 nm laser entering the BBO crystal. While ensuring the transmittance of 266 nm deep ultraviolet laser, in order to increase the damage threshold of the film system, the BBO crystal is coated with 266 nm ultraviolet protective film at both ends. The size of the type I critical phase matching BBO crystal is 5 mm×5 mm×4 mm, and the cutting angle is θ=47.7°, φ=0° (room temperature). In the experiment, in order to accurately adjust the angle and temperature of the BBO crystal, it is also placed in the copper furnace and then fixed on the three-dimensional rotating table. Finally, the generated 266 nm deep ultraviolet laser passes through two 532/266 nm DM filters to remove the 532 nm laser residual beam, and its output power is measured with a power meter.