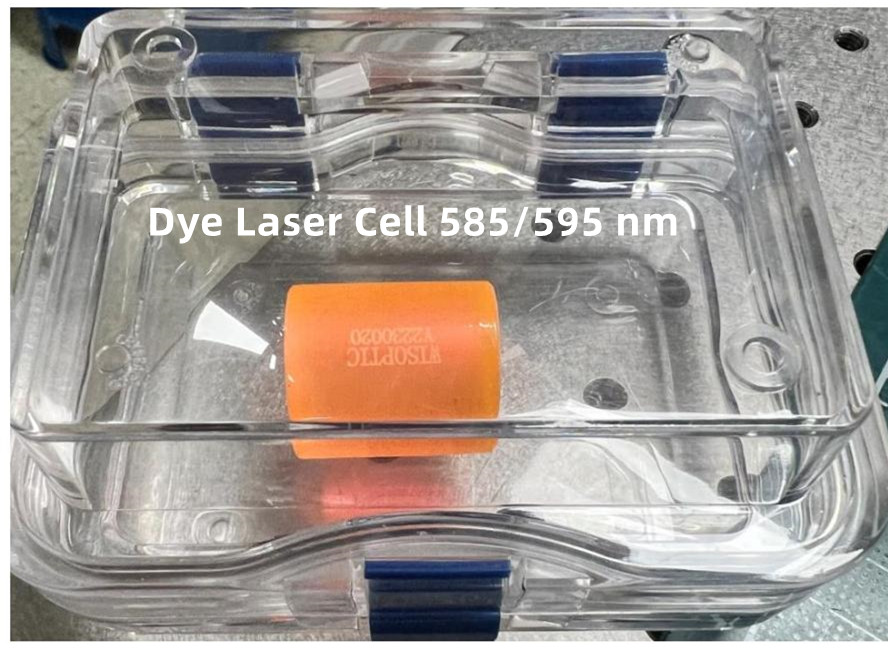

Solid Dye Laser Rods 585nm, 595nm, 650nm, 660nm

• Totally made in-house and customer design are available

• Narrow band output with wavelength 585nm, 595nm, 650nm, and 660nm

• High output energy

• High conversion effeciency of input-output energy

• Stable performance of long-time operation

• Fast delivery with mass production capability

• Very competitive price

Polymer-matrix Gain Medium for Pulsed Dye Laser (PDL)

Polymer matrix can be used to make solid laser gain medium of dye lasers. Compared with the commonly used liquid-state dye laser unit, the solid-state material has many advantages, such as the convenience of handling, the various options of dimensions and shapes.

But the dye molecules in the polymer matrix might degradate in a limited time

by triplet excitation, or even destruct permanently. To avoid this shortage, WISOPTIC provides long quality guarantee period of every piece of Dye Laser Cell/Rod made in-house.

WISOPTIC's Dye Laser Cell 585/595nm and 650/660nm are developed in-house and then be used to make dye laser handpieces. With dye laser handpieces, it's very easy to produce laser beam at 585/595nm or 650/660nm (only need a normal laser source of 532nm). Dye laser 585/595nm is used mainly to treat facial telangiectasia, and dye laser 650/660nm is for removal of green tattoo, etc.

Dye laser handpiece made from WISOPTIC has very high conversion efficiency: 65%~75% for 532/585nm, 45%~55% for 532/650nm.

Out put energy higher than 100mJ @ 585/595, and > 70mJ @ 640/660nm.

25 ± 0.5 mm (or customized size) | |

Diameter | 25 ± 0.2 mm (or customized size) |

Beam diameter | Input: 8 mm; Output: 2~3 mm |

Parallelism of end faces | ≤ 1’ |

Coating | Uncoated |

Conversion efficiency | 532-585nm: 65%~75%; 532-650nm: 45%~55% |

Material | Proprietary trade secret |

Life time | > 40K pulses |