Study on thermal characteristics of 266 nm deep ultraviolet laser generated by BBO crystal - 03

03 Experimental results and analysis

By optimizing the cavity length parameters of Nd:YVO4 (www.wisoptic.com) laser under high-power pump injection, a 1064 nm high peak power narrow pulse laser output with an average power of 26 W, a repetition frequency of 20 kHz, and a single pulse width of 5 ns was obtained when the 888 nm pump light power was 65 W; after the 1064 nm fundamental frequency infrared light was doubled by the LBO crystal, a 532 nm laser with a maximum power of 16 W was finally obtained, and the infrared to green light conversion efficiency reached 61.5%. The beam quality factor M2=1.2 was tested by the beam profiler, and the power stability within 3 hours was better than 2% (root mean square, RMS).

After the cavity-dumped all-solid-state Nd:YVO4 laser and its frequency doubling system were optimized, in order to study the temperature change inside the BBO (www.wisoptic.com) crystal with different matching temperatures during the frequency quadrupling process and its influence on the output power of the deep ultraviolet laser, the output power of the 266 nm deep ultraviolet laser obtained under the green light injection of 4 W, 8 W, 12 W and 16 W was recorded at the crystal matching temperature of 60 ℃, 120 ℃ and 180 ℃ respectively. The curves of the change of the crystal heating device temperature are shown in Figure 2. It is worth noting that this paper realizes the transformation of the crystal matching temperature by precisely adjusting the angle of the BBO crystal at an extremely low output power of the ultraviolet laser (0.05 W).

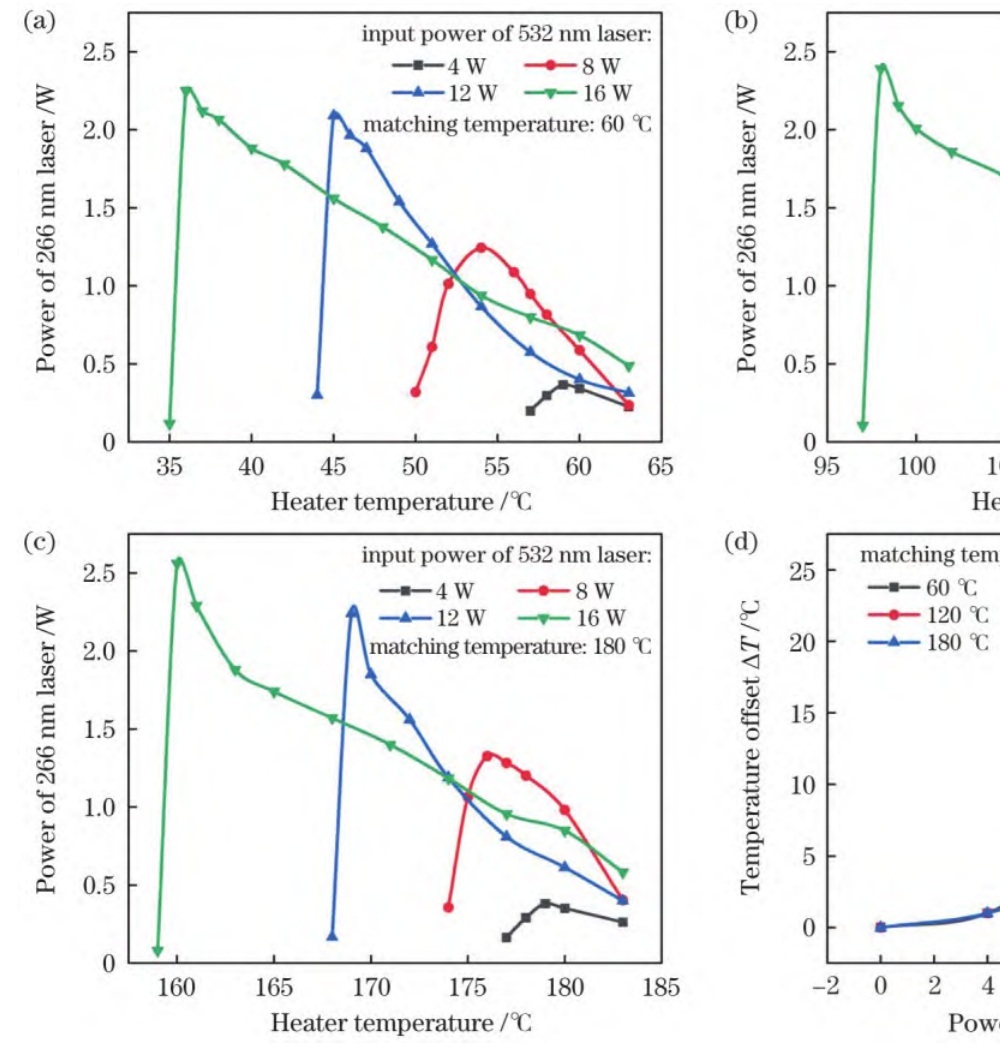

Fig. 2 Output power of 266 nm DUV laser under different green light injection powers varies with the temperature of the crystal heater at different phase matching temperatures. (a) 60 ℃; (b) 120 ℃; (c) 180 ℃; (d) temperature offset ΔT of the crystal heater varies with the input power of 532 nm laser at different phase matching temperatures of the crystal

As can be seen from Figure 2 (a), when the crystal matching temperature is 60 ℃, as the green light input power gradually increases from 0 W to 4 W, 8 W, 12 W and 16 W, the temperature of the crystal heating device decreases continuously when the optimal power ultraviolet light output is achieved, from 60 ℃ to 59 ℃, 53 ℃, 45 ℃, and 36 ℃. In other words, as the green light input power increases, the heat generated inside the BBO crystal also increases accordingly, so the temperature of the crystal heating device needs to be continuously scanned in the low temperature direction to maintain the crystal matching temperature unchanged in order to meet the phase matching conditions when the optimal power ultraviolet light output is achieved. When the input power of the 532 nm laser is 16 W, the temperature offset ΔT of the heating device reaches 24 ℃, and the maximum output power of the 266 nm laser is 2.25 W. When the crystal matching temperature is gradually increased to 120 ℃ and 180 ℃, the temperature offset ΔT of the BBO crystal heating device gradually decreases from 24 ℃ to 22 ℃ [Figure 2(b)] and then to 20 ℃ [Figure 2(c)], and the maximum output power of the 266 nm laser also increases from 2.25 W to 2.39 W and 2.56 W. Since the heat conduction between the crystal and the heating device and between the heating device and the outside world is negligibly affected by temperature, the reason why the temperature offset ΔT of the heating device decreases with the increase of matching temperature can be directly attributed to the decrease of heat generation of the crystal itself. This result also shows that increasing the crystal matching temperature can effectively slow down the thermal effect inside the crystal and improve the power output of deep ultraviolet laser. Although further increasing the crystal temperature from 180 ℃ may yield higher power, considering the difficulty of further temperature control in actual work and the stability of the temperature control device, the crystal matching temperature is ultimately controlled below 180 ℃.

Figure 2 (d) shows the curve of the temperature offset ΔT of the heating device when the crystal with different matching temperatures is quadrupled as a function of the green light input power. The specific results are shown in Table 1.