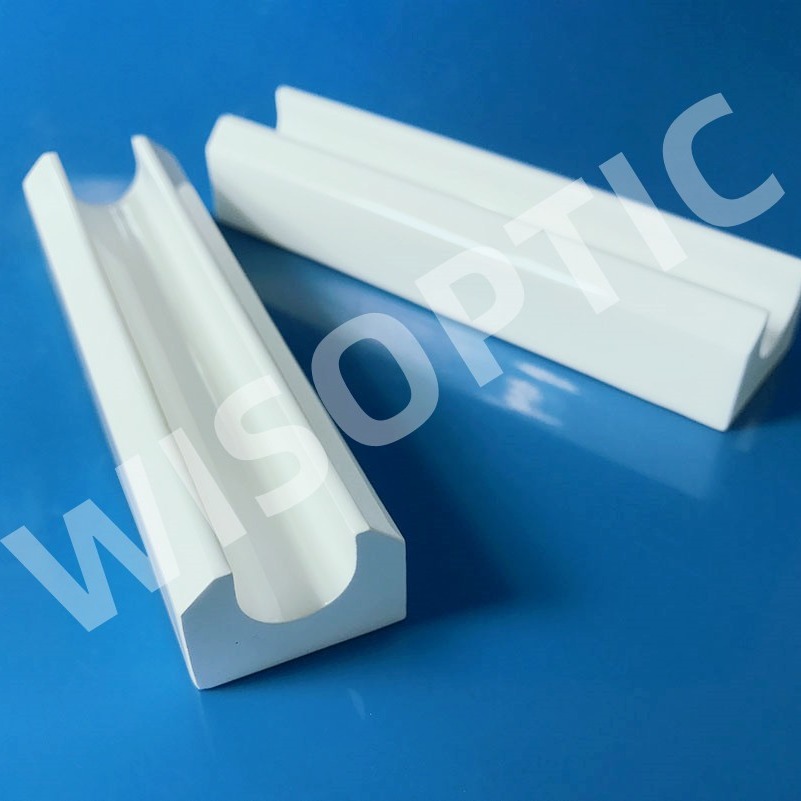

Ceramic Laser Reflectors

Ceramic Laser Reflectors from WISOPTIC have the following benefits and improvements over those made with materials such as polymer and metal:

• Higher efficiency/output performance

• Prolonged life time

• Higher reflectance over a broader range of wavelengths

• Uniform beam quality

• Inert to all regular cleaning chemicals

• Greater thermal stability, mostly at higher temperatures because of a very low coefficient of thermal expansion

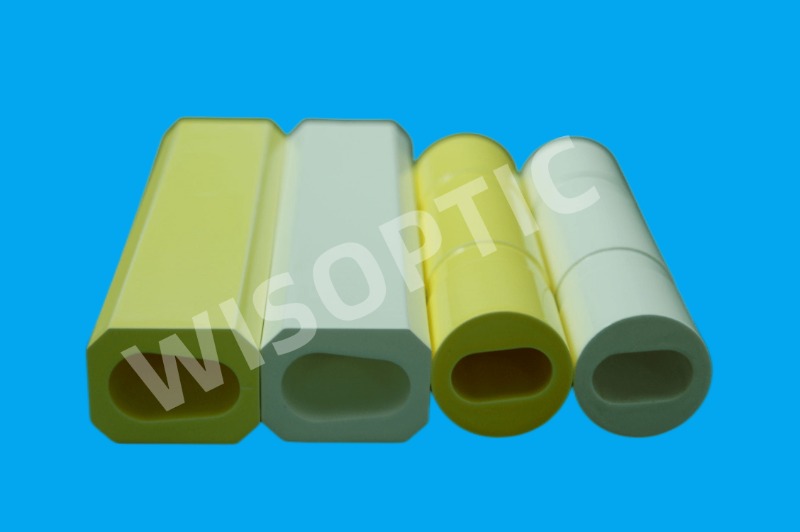

The Ceramic Laser Reflectors are high reflectance cavities used in solid state and CO2 laser systems. They are built either as a one-piece or two-piece system based on customer requirement.

Ceramic cavities produce diffuse reflectance, which offers a very uniform beam profile. This diffuse reflectance also distributes light and consequently decreases hot spots in the pumped medium. These completely dense materials (e.g. Al2O3) exhibit higher strength and scratch resistance than traditional polymeric and thermoplastic materials. Moreover, the mechanical strength of the material allows the design and manufacturing of thin wall section reflectors to lessen the laser’s final assembly weight and design space necessities.

The reflectors can be glazed entirely or partly according to specified applications. WISOPTIC’s Ceramic Laser Reflectors can be found in a broad range of applications including:

• Intense Pulse Lamp (IPL) systems for use with tattoo and hair removal

• Industrial lasers for use with welding, cutting and marking

• Medical lasers used in surgical and ophthalmic applications

• DPSS lasers for use in medical and scientific applications plus range finders

A broad range of standard and custom designed reflectors with varying glaze combinations are available.