INDUSTRY NEWS

3.4 Laser pretreatment of DKDP component The laser-damaged precursor of DKDP crystals (provided by WISOPTIC) is in the material body, so it is different from the removal of surface nodule defects in dielectric films. Laser pretreatment cannot remove the precursors in the body, but can only reduce

2023/03/21 11:11

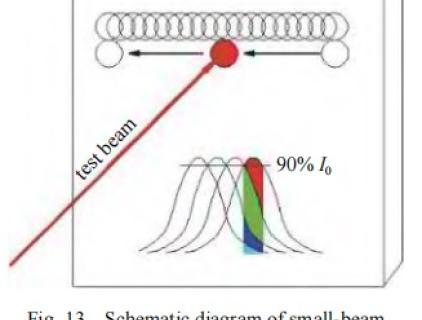

3.3 Laser pretreatment of dielectric film with large diameter Laser pretreatment technology is the last process before the supply of large-diameter components with dielectric film in NIF devices in the United States. LLNL provides their laser pretreatment device and specifications to each of their

2023/03/16 17:58

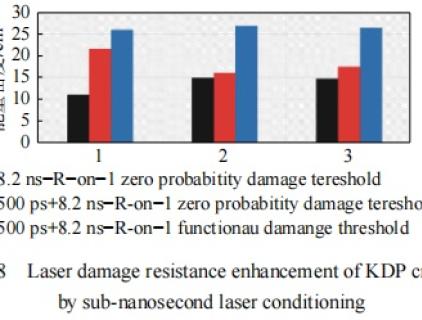

3.2 Laser Pretreatment TechnologyLaser pretreatment is a technology that uses sub-threshold laser energy flow to process components before they are practically used. It can effectively improve the ability of some optical components to resist laser damage. The main function of laser pretreatment is

2023/03/09 11:29

3 Functional laser damage evaluation and laser pretreatment technologyWhether it is microscopic defects or nanoscopic laser damage precursors, the distribution and amount in optical materials or components are closely related to the manufacturing process. Low-defect processing and manufacturing

2023/03/01 10:36

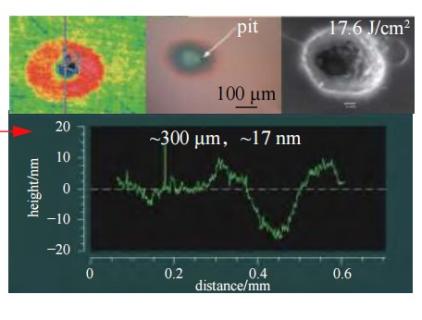

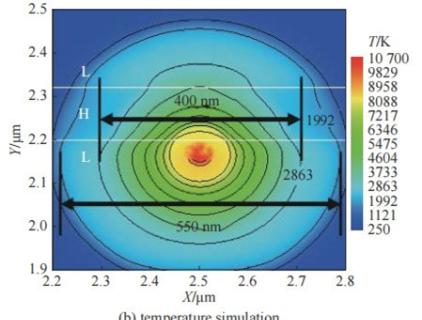

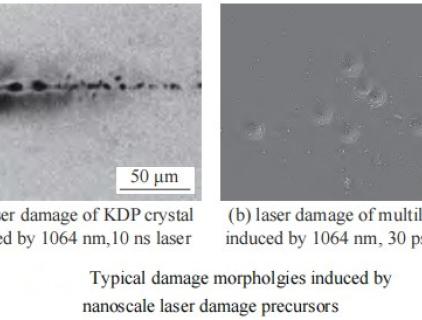

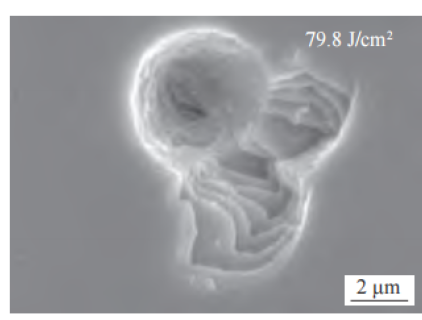

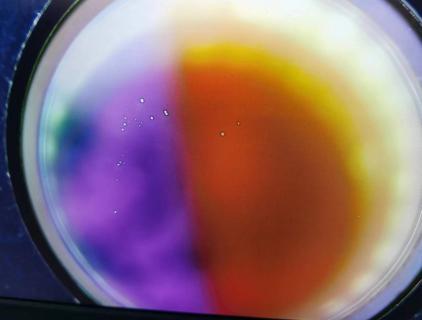

2.2 Theoretical inversion cognition of precursor characteristics through damage morphologyThe typical damage morphology of multilayer dielectric films with picosecond pulse in the fundamental frequency band is high-density and small-scale. In order to understand the destruction process, we designed

2023/02/23 15:23

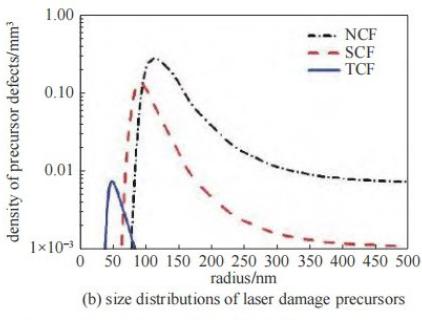

2.1 Manipulating and understanding laser damage precursors through material growth processesCombined with the statistical model, information such as precursor density and threshold distribution can be extracted from the damage probability curve, which indirectly reflects the information of the

2023/02/17 12:39

Nanoscale laser damage precursorsDifferent from microscopic defects, defects are called precursors here. Defects generally refer to observable microstructures that are different from the characteristics of the surrounding matrix materials, and are often observed by optical microscopy. The

2023/02/11 11:46

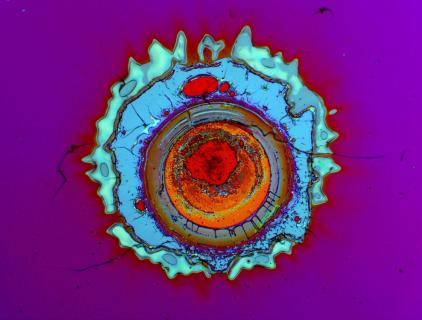

Laser damage induced by microscopic defects in optical componentsAccording to the above numerical analysis results, it can be seen that cracks may be generated around the nodule seed and propagate along the radial direction. However, considering that the boundaries of nodules are usually relatively

2023/01/29 13:57

Laser damage induced by microscopic defects in optical componentsNodule defect is a typical representative of microscopic defects, and it is one of the main discoveries in the study of laser damage to thin films in the 1990s. At present, a lot of research has been done on the electric field

2023/01/25 19:58

Since defects induce laser damage, and defects are randomly distributed in optical components, the detection and evaluation of laser damage performance of optical components has become another important research content. The standard for laser damage threshold testing was established in the 1990s

2023/01/21 12:30

Based on the basic principles of laser damage, researchers have found a breaking through point to solve the problem of laser damage to optical components. But it is very difficult to effectively suppress the source of laser damage in the manufacturing process. Given the variety and complexity of

2023/01/15 19:38

In 1962, the American scientist McClung F J reported for the first time that the silver mirror of the ruby laser resonator had hole burning damage, which was the first public report on the laser damage of optical components. The subsequent invention of Q-switching technology and mode-locking

2023/01/05 17:52