INDUSTRY NEWS

1.3 Doping of Lithium Tantalate CrystalDifferent fields have different requirements for the properties of lithium tantalate crystals. When being used to prepare high-density and large-capacity holographic information storage devices, LiTaO3 crystals need to have excellent photorefractive properties

2023/09/05 15:11

1.2 Near-stoichiometric Lithium Tantalate Crystal Most of the lithium tantalate crystals currently used are grown from melts with the same composition ratio, which is generally called the same composition lithium tantalate (CLT). However, large number of defects affect the physical properties of

2023/08/24 10:54

IntroductionLithium tantalate (LiTaO3, referred to as LT), as an excellent multifunctional crystal material, has good piezoelectric, electro-optical and pyroelectric properties, and is ideal for making surface acoustic wave (SAW) filters, resonators, tuners, Q switches and pyroelectric detectors.

2023/07/29 20:51

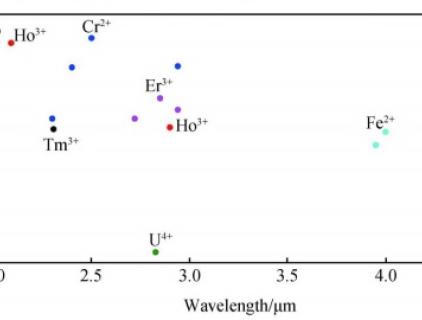

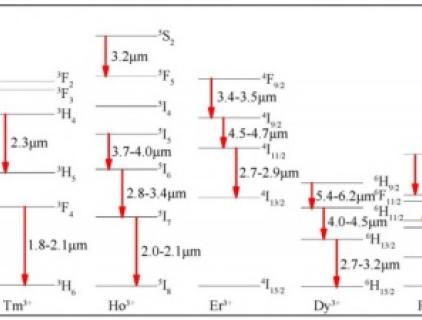

Conclusion Considering comprehensive factors such as wide absorption bandwidth, large absorption cross section, long upper energy level lifetime (ms to tens of ms) (see Table 2), ion cross relaxation, increased quantum efficiency, and mature LD pump source, Tm3+ in the 2 μm band, Ho3+ and Er3+ in

2023/06/23 17:30

1.5 ~ 4 μm laser crystals doped with Fe2+ Compared with Cr:ZnSe, Fe:ZnSe has a smaller band gap and is prone to produce thermally induced multi-phonon quenching, so both laser power and efficiency are low. In 1999, Adams et al. realized the tunable wavelength of 3.98-4.54 μm at low temperature for

2023/06/08 17:06

1. 4 ~ 3 μm laser crystals doped with Er2+, U4+, Ho3+, Dy3+ As an active ion, Ho3+ has achieved laser output in the ~3 μm band (5I6→5I7). In 1976, researchers first realized 2.9 μm laser output in Ho:YAP crystal. In 1990, Bowman et al. obtained 2.85 μm and 2.92 μm laser outputs in Ho:YAP crystals

2023/05/30 10:27

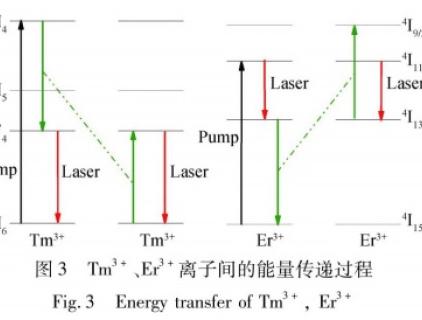

1. 4 ~ 3 μm laser crystals doped with Er2+, U4+, Ho3+, Dy3+ Similar to the 2μm band (3F4 → 3H6) of Tm3+, there is an energy transfer up-conversion process (Energy transfer up-conversion, ETU) between Er3+ ions, and the cross-relaxation process:ETU1 (Er3+: 4I13/2 + Er3+: 4I13/2 → Er3+: 4I9/2 + Er3

2023/05/19 19:01

1. 3 2 ~ 3 μm laser crystals doped with Cr2+ The mid-infrared luminescence of transition metal ions (Ni2+, Co2+, Cr2+, Fe2+, etc.) is based on 3d→3d transitions. According to the different types of sites occupied by transition metal ions in the host material, they can be divided into two categories

2023/05/10 10:56

1. 2 ~ 2.3 μm laser crystals doped with Tm3+ Compared with the 2 μm band (3F4 → 3H6) of Tm3+, the 2.3 μm laser operation based on the 3H4 → 3H5 transition of the Tm3+ doped laser medium has the following advantages: (1) ~790 nm LD is directly pumped to the upper energy level of the laser. Tm3+

2023/04/17 11:38

1. ~ 2 μm laser crystals doped with Tm3+ or Ho3+Tm3+ has a strong absorption near ~790 nm and a large absorption cross-section, so the ~790 nm commercial LD can be directly used as a pump source. Another feature and advantage of this band is that there is a cross-relaxation (CR) energy transfer

2023/04/10 17:40

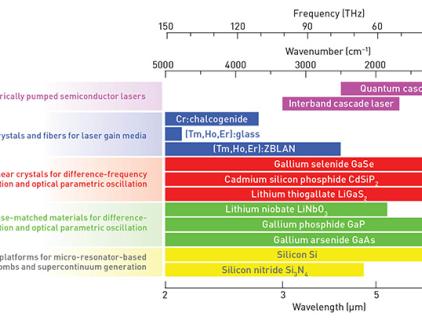

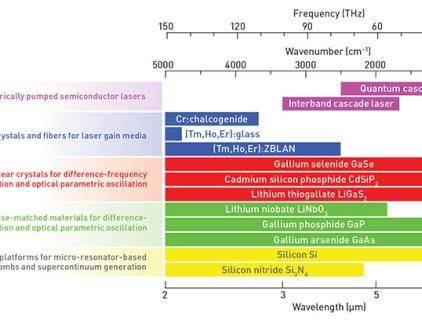

1. Research status and future development trend of mid-infrared (2-5 μm) laser crystalsAccording to the order of laser wavelength from short to long, the main material that have achieved laser output (including some optical fibers and transparent ceramics for comparison) are listed in Table 1.

2023/04/05 18:19

2-5 μm mid-infrared laser crystals have important applications in directional infrared countermeasures, anti-terrorism, biomedicine, environmental monitoring, optical communications, strong field physics, laser fusion, and mid-to-far infrared (nonlinear frequency conversion) basic light sources,

2023/03/29 12:05